In the world of precise temperature measurement, resistive temperature sensors are a cornerstone of modern industry and technology. Among them, RTD temperature sensors and NTC thermistors are two of the most prominent solutions. While both convert temperature into an electrical signal, they operate on different principles and excel in distinct applications. This guide will help you understand their characteristics to make an informed choice.

The table below summarizes the fundamental distinctions between these two sensor types.

|

Feature |

RTD (Pt100) / PRT temperature sensors |

NTC Temperature Sensors |

|

Working Principle |

Resistance increases with temperature (Positive Temperature Coefficient) |

Resistance decreases with temperature (Negative Temperature Coefficient) |

|

Core Material |

Platinum (Pt) |

Metal oxide semiconductor ceramics |

|

Accuracy & Stability |

Very high accuracy and excellent long-term stability |

High accuracy in a narrow range; stability is affected by aging |

|

Temperature Range |

Wide, e.g., -200°C to +650°C |

Narrower, typically -40°C to +150°C |

|

Linearity |

Good, approximately linear response |

Nonlinear (exponential) response, requires linearization |

|

Cost |

Higher |

Lower, cost-effective |

|

Typical Application |

Industrial process control, laboratory precision measurement, HVAC |

Consumer electronics,home appliances, battery temperature monitoring |

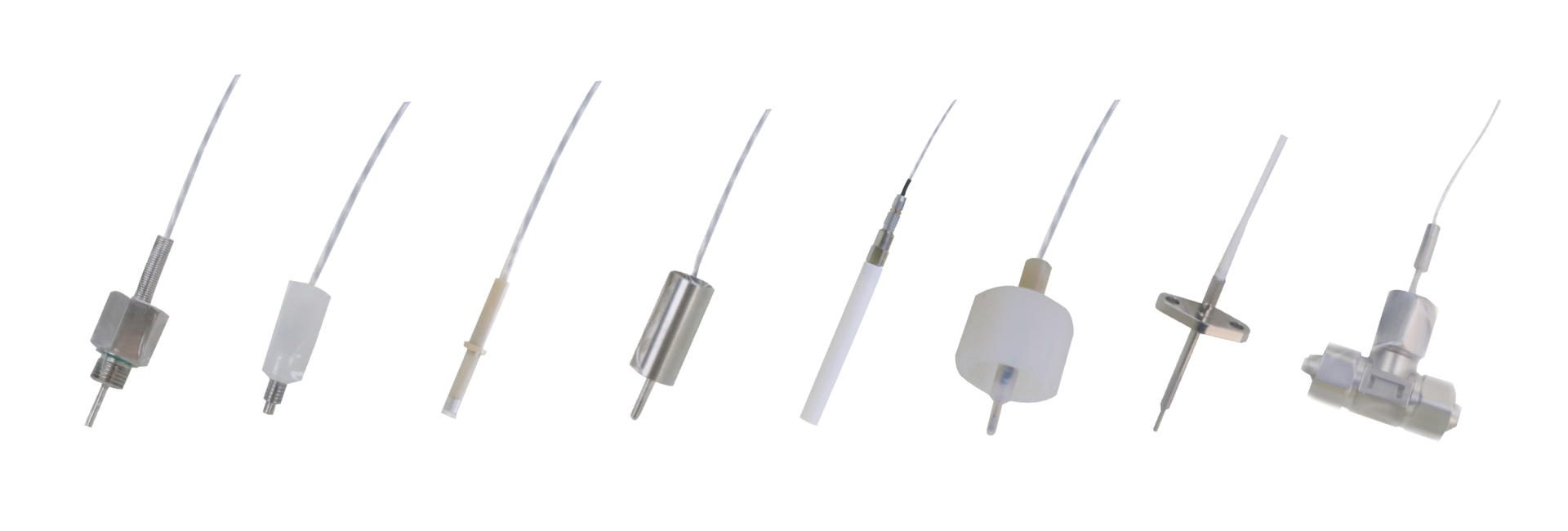

RTD temperature sensors, also known as PRT temperature sensors, rely on the predictable property of pure metals, typically platinum, to increase resistance as temperature rises . The most common type is the PT100 PRT probe, which has a resistance of 100 ohms at 0°C .

Their key advantage is high precision and exceptional long-term stability. Thanks to the stable nature of platinum, these sensors drift very little over time, making them reliable for critical measurements over many years . They also feature a relatively linear resistance-to-temperature curve, which simplifies signal processing . Standardization under IEC 60751 ensures that PT100 probes from different manufacturers are easily interchangeable .

However, they are generally more expensive than NTC temperature sensor, and have a lower sensitivity (smaller resistance change per degree of temperature). They can also be more physically bulky, leading to a slower response time . For high-accuracy applications, they require complex measurement circuits (3 or 4-wire configurations) to eliminate errors from lead wire resistance .

NTC thermistors are made from semiconductor ceramics. Their resistance decreases exponentially as temperature increases—a property known as a Negative Temperature Coefficient .

Their most significant advantage is extremely high sensitivity. A small temperature change results in a large resistance change, making them easy to measure . They are also very cost-effective and can be manufactured in very small sizes, leading to fast response times .

The primary challenge with NTCs is their strong nonlinearity. Converting their resistance output to an accurate temperature reading requires complex mathematical equations or lookup tables . They also have a narrower temperature range and can suffer from aging, meaning their resistance values may drift over time, making them less suitable for long-term precision tasks . Unlike RTDs, there is no universal international standard for their characteristics, which can complicate replacement .

For applications demanding high precision NTC performance in a compact size, advanced solutions like certain analog temperature sensors can serve as alternatives, offering high linearity and simplifying design .

Selecting between an RTD and an NTC depends on your project's priorities.

Choose an RTD (like a PT100) if: Your application demands high accuracy, excellent long-term stability, and a wide temperature range. They are the preferred choice for industrial process control, scientific research, and HVAC systems where reliability over years is critical .

Choose an NTC Thermistor if: Your priorities are low cost, high sensitivity, and fast response in a small package. They are ideal for consumer electronics, household appliances, and battery management systems where absolute precision over a wide range is less critical .

In summary, RTDs are the masters of precision and stability, while NTCs excel in sensitivity and cost-effectiveness for controlled environments. Understanding these differences is key to selecting the right temperature probes for your needs.

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 Hefei Zhice Electronics Co., Ltd.. All Rights Reserved. Sitemap / Blog / XML / Privacy Policy

Network Supported

Network Supported